| Model | SS-10L | SS-20L | SS-30L | SS-50L |

| Reaction Capacity | 10L | 20L | 30L | 50L |

| Jacketed Volume | 3L | 6L | 10L | 16L |

| Material | SS304( SS316 optional ) | |||

| Thickness | Lining:4mm, shell:4mm | |||

| Motor | 200W | |||

| Rotating speed | 0-600rpm | |||

| Controller | Speed adjustment, temperature and speed LCD digital display | |||

| Voltage | 110V/220V, 50/60Hz | |||

| Working pressure | -0.1~0.49Mpa. | |||

| Vacuum seal | 0.098Mpa | |||

| Nine port on lid (According your demand) |

Stirrer port:32# Mechanical seal | |||

| Solid feeding port with view mirror:Φ55 Union | ||||

| Temperature measuring port:Φ19 Quick-opening valve | ||||

| Reflux port:Φ38 Quick-opening valve | ||||

| Exhaust port: DN20 Ball valve | ||||

| View/Lighting port:Φ38 Union | ||||

| Nitrogen gas port: Φ8mm LOK-Fittings | ||||

| Constant pressure drop funnel port: Φ19 Quick-opening valve | ||||

| Pressure gauge:φ8mm Female Thread | ||||

| Condenser | Stainless steel serpentiform condenser | |||

| Discharge valve | DN32 Ball valve | |||

| PTFE Stirrer | Φ14 Four-blads, two layer, other styles are available | |||

| Frame | 304 Stainless steel | |||

| Inlet/outlet oil port | DN25 Male Thread | |||

| Machine size(mm) | 700*600*2030 | 750*650*2150 | 750*650*2450 | 750*650*2450 |

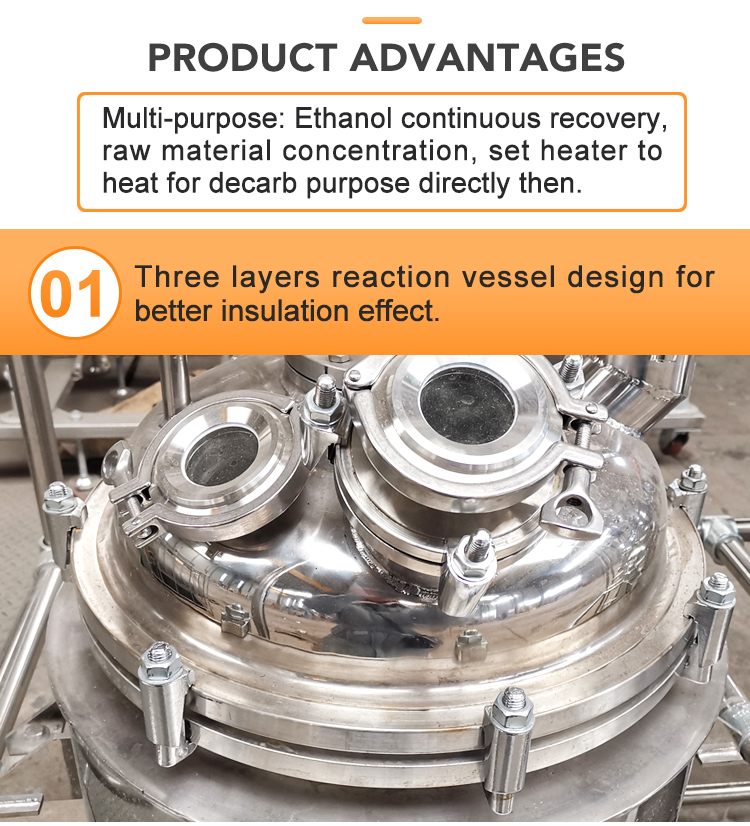

Working principle of stainless steel reactor

When the stainless steel reactor is working, the external permanent magnet is driven by the motor (or motor reducer) to rotate, and at the same time, the other permanent magnet and the rotor enclosed in the isolating sleeve are coupled to rotate synchronously, so that the external power can be transferred without contact and friction. It is transmitted to the internal rotor, and is integrated with the lower shaft and the stirring blade through a coupling to achieve the purpose of stirring in the stainless steel reactor.

Stainless steel reactor structure

The stainless steel reaction kettle is composed of a kettle body, a kettle cover, a jacket, a stirrer, a transmission device, a shaft sealing device, and a support.

Stainless steel reactor has the characteristics of rapid heating, high temperature resistant, high pressure resistance, corrosion resistance, health, no environmental pollution, easy to use. etc. Widely used in chemical, food, coating, hot melt adhesive, silica gel, paint, medicine, petrochemical production of reaction, evaporation, synthesis, polymerization, saponification, sulfonation, chlorination, nitrification and other processes of pressure reactor.

Description

Ai 316L Grade Stainless Steel Reactor Features:

Dual jacketed. Sealed outer insulation jacket provides best temperature performance inside chamber

All wetted parts on main vessel and lid built with pharmaceutical grade 316L SST

Shell and tube heat exchanger with 70 tubes for the best condensing results

ElectroPolished internal chamber

Greatly reduces surface roughness by leveling micro-peaks and valleys

Improved vacuum pressures, out-gassing rates, and pumping speed

Prolong equipment lifespan by reducing friction and wear

Much better sterilized and semiconductor grade surface

Detachable condenser and collection tanks

Dual collection tanks with big sight glass allows you to drain without breaking vacuum

High drain port clearance for easy draining or added filtration

Large ports (top 12″ bottom 6″) allows easy chamber cleaning

Top placed vacuum port on condenser provides better flow and condensing results

No messy cable, with space saving integrated stirring motor controller

Heavy-duty stainless-steel frame with swivel casters

Built-in flashlight gives you a clear view inside the chamber

Positive/negative pressure gauge

Matte finish stainless steel

Customizable lid for various application

Tons of tri clamps adapters available, e.g. tri clamp to hose barb/KF25/NPT

Choice of bolted or pin clamp for various pressure applications

Flexible bellow condenser connection reduces shipping damage

Electric motor and controller model is ETL certified to UL and CSA standards (optional)

Peer reviewed model (pneumatic motor and controller) is approved to be used with Acetone, Ethanol, Heptane, Hexane, Isopropyl Alcohol, Methanol, and Pentane. (optional)

CAUTION!

Never fill circulated heaters or chillers with water, always use Ai or manufacturer’s recommended thermal fluid

Always leave ample fluid space in heater reservoir to allow fluid heat expansion

Always keep system vacuum passage or drain valve open when heating up circulation jackets

Always make sure your vacuum pumps and diffusion pump fluid is clean and within limits